Transfer Options for Large Volumes of Powder

To successfully convey solids, there are a number of factors that need to be considered. This includes transfer rate, transfer distance, product characteristics, quantity, and level of containment required (just to name a few). Given the range of issues involved, it’s easy to see why there is no single solution that will apply to all applications. And while each one is important in its own right, the quantity of material involved can be especially important when considering all the options available.

When transferring a sizeable volume of solids, it usually involves integrating three components to create a complete solution:

- Some type of container that temporarily stores the material in need of being transferred

- A mechanism or station to assist in facilitating the discharge from the primary location

- An apparatus that carries out the transfer of material (empties the container/fills the secondary vessel)

Let’s focus on what your best options are for each of these components when you need to move a significant amount of material from one place to another in a safe, contained manner.

Bags/Containers

When you need to transfer large volumes of material, it is too labor intensive to rely on an operator to stand for long periods of time and introduce materials to the system through a charging lance. Plus, this arrangement would require using multiple drums or containers which not only adds unnecessary clutter to the work area, but transferring by lance from open containers also reduces the level of containment that is achieved, which can lead to dust exposure and other housekeeping issues.

When transferring larger quantities of powders, many companies incorporate FIBC’s or “Bulk Bags” to carry out both single powder and multiple powder transfer. These containers can be used for relatively small batch operations as well as larger production campaigns, and can provide a high level of containment during transfer. These types of containers, when integrated into a closed transfer system, provide an ideal solution for applications that require large quantity transfer with minimal labor.

There are many advantages in using flexible bulk containers in your transfer solution (one of which – flexibility – is mentioned in its name!). Bulk bags are extremely cost effective and even customizable, taking into account material properties as well as filling and discharge conditions. And unlike drums and other rigid containers that take up a large amount of space regardless of if they are full or empty, FIBCs take up very little space when empty. They have a low packaging weight with the ability to carry up to a thousand times their own weight. Additionally, there are recycling and recondition opportunities, making big bags a green choice (that of course depends on the material they are being used for; some that contain hazardous material don’t have that capability).

Big Bag Stations/Bag Discharge Systems

With all due respect to the bag, it really is only as good as the station that facilitates its discharge. There are various arrangements and options, but essentially a big bag discharge system is comprised of:

- Loading mechanism – there are various methods that can be used including an integral hoist system, customer supplied hoist, or forklift

- Impactors – to help with material flow from the bulk bag into the discharging system, impactors are often incorporated to push the material towards the center of the bag to prevent bridging or rat-holing.

- Massagers – these frames raise and lower the bottom of the bulk bag from both sides to push material into the flow path.

- Discharge Gate – this feature safely and quickly closes bulk bag discharge spouts for operator tie off, allowing partial bag discharging of your materials.

- Bag Sealing System – to enable dust-tight discharge at the spout interfaces

- Material Conditioning – de-lumping, granulation, preventing ratholes and bridging, fluidizing gas introduction and discharge pressure control.

- Controls – bring automation to your transfer solution with a control package that can be custom designed for your application requirements. From loss in weight scale systems and fully automated PLC controls to intrinsically safe or explosion-proof controls for hazardous locations, many options are available.

Transfer Technology

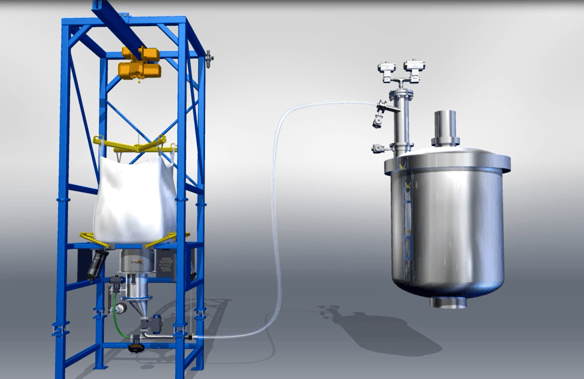

A major part of any powder handling system is the apparatus that transfers the material from its source container, and delivers it into the secondary receiving vessel. For larger volumes that utilize a Big Bag System and require a high level of containment, pneumatic conveying is often the most suitable technology to accomplish transfer. Typically, the pneumatic transfer unit is mounted on the receiving vessel, and a flexible hose connects it to the Bulk Bag Discharger. Then, using a series of vacuum and/or pressure sequences, the apparatus moves the material into the vessel.

Observing an operation like this in action, it’s clear to see that while all the components play an essential role in creating a complete solution, the transfer unit is really the heart of the process. De Dietrich Process Systems’ powder handling solutions all incorporate the Powder Pump, a device that safely and efficiently transfer powder from one location to another. When installed together, the Big Bag Station and the Powder Pump offer a comprehensive solution for large volume transfer by creating a complete, integrated system with a modular design that offers the flexibility needed to accomplish a variety of powder transfer requirements.